Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Drying & Coating>Energy Saving Drying Equipment --Square/Round Vacuum Dryer(CE & PED)

Energy Saving Drying Equipment --Square/Round Vacuum Dryer

(CE&PED Approved)

1.Descriptions

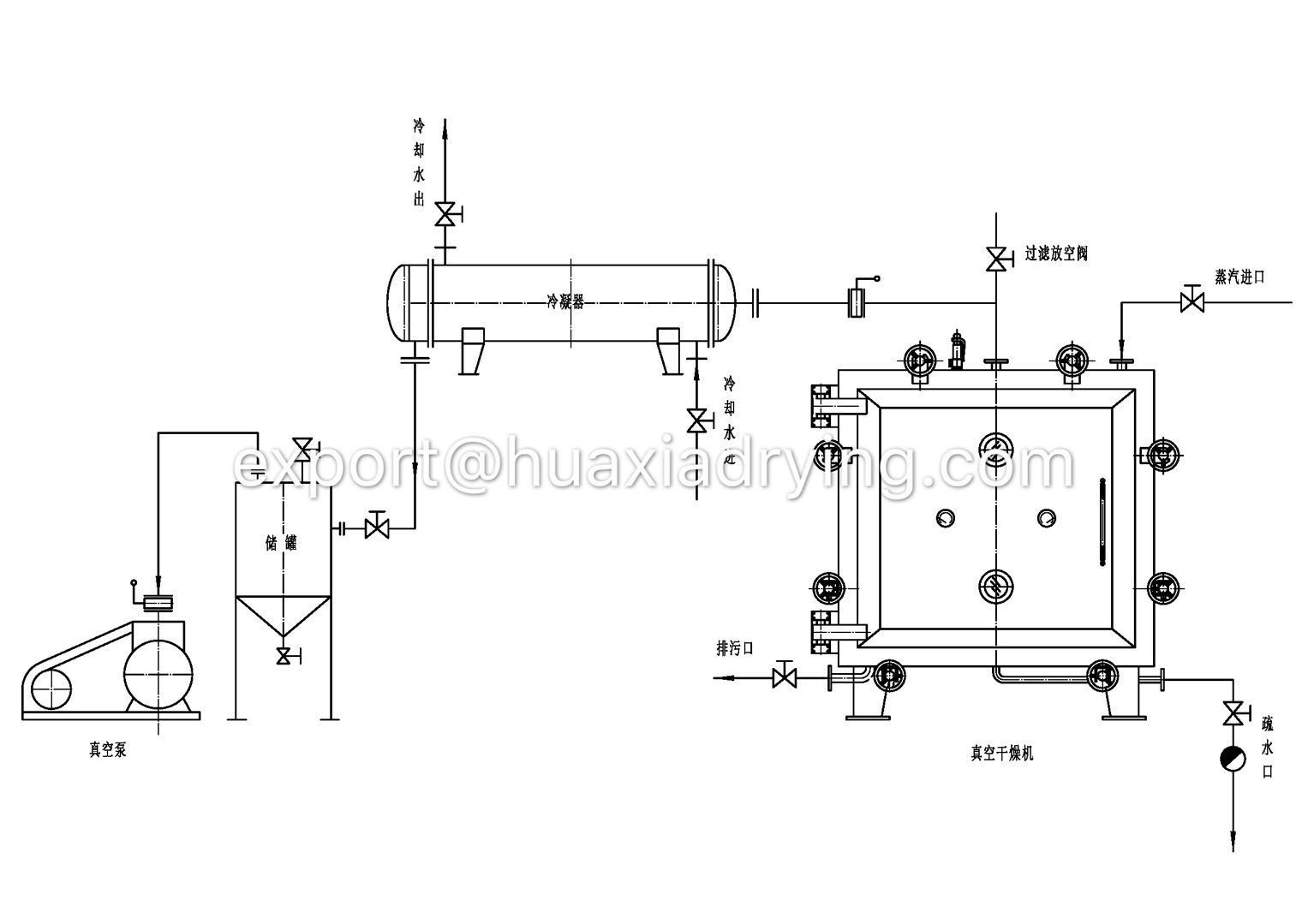

FZG/YZG Series Vacuum Dryer is a new generation drying device developed by our factory on the basis of combining the technology of similar equipment. The whole system include vacuum drying room , instrument gauge ,vacuum system , heat source , control cabinet ,etc…

2.Principle

Raw material with moisture (solvent) tiling on the tray , tray was putting on the heating jacket plate ,heating media transfer the heat to the material , moisture(solvent) evaporated and being removed by vacuum system discharged as exhaust , then the material being dried , since most of material has low boiling point in vacuum condition , the vacuum dryer suit for the material which need low drying temperature .

3.Applications

It is suitable for the raw materials that need to concentrate, mixed and dried at low temperature (for example, biochemistry) products in chemical, pharmaceutical and foodstuff industries. It is particularly suitable for the raw materials that are easy to be oxidized, volatilized and have light sensitivity and is toxic and not permitted to destroy its crystal in drying process.

◆ Thermal sensitive raw materials that cannot stand high temperature.

◆ Materials with solvent and dangerous gases to be collected.

◆ Materials that are dangerous and easy to oxidize.

◆ Materials that require low content of volatile residual.

◆ Materials that have special requirements for crystal shape.

4.Technical Parameters

Model |

YZG-600 |

YZG-800 |

YZG-1000 |

YZG-1400A |

FZG-10 |

FZG-15 |

FZG-20 |

Inner size(mm) |

φ600×976 |

φ800×1247 |

φ1000×1527 |

φ1400×2054 |

1500×1060× |

1500×1400 |

1500×1800 |

Outside size(mm) |

1135×810× |

1700×1045× |

1693×1190× |

2380×1675×1920 |

1924×1720 |

1513×1924 |

1924×2500 |

Tray level |

4 |

4 |

6 |

8 |

5 |

8 |

12 |

Distance between tray level(mm) |

81 |

82 |

102 |

102 |

122 |

122 |

122 |

Tray size(mm) |

310×600×45 |

520×410×45 |

520×410×45 |

460×640×45 |

460×640 |

460×640 |

460×640 |

Tray number |

4 |

8 |

12 |

32 |

20 |

32 |

48 |

Working pressure in pipe(MPa) |

≤0.784 |

≤0.784 |

≤0.784 |

≤0.784 |

≤0.784 |

≤0.784 |

≤0.784 |

Working Temperature(℃) |

35-150 |

35-150 |

35-150 |

35-150 |

35-150 |

35-150 |

35-150 |

pressure in dryer(MPa) |

-0.1 |

-0.1 |

-0.1 |

-0.1 |

-0.1 |

-0.1 |

0.1 |

Evaporating Capacity(kg/m2·hr) |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

Vacuum pump(use cooler) |

2X-15A 2KW |

2X-30A 3KW |

2X-30A 3KW |

2X-70A 5.5KW |

2X-70A 5.5KW |

2X-70A 5.5KW |

2X-90A 2KW |

Vacuum pump(no cooler) |

SZ-0.5 1.5KW |

SZ-1 2.2KW |

SZ-1 2.2KW |

SZ-1 2.2KW |

SZ-2 4KW |

SZ-2 4KW |

SZ-2 5.5KW |

Weight of dryer(kg) |

250 |

600 |

800 |

1400 |

1400 |

2100 |

3200 |