Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Mixing & Blending>Three-dimensional Mixer(CE)

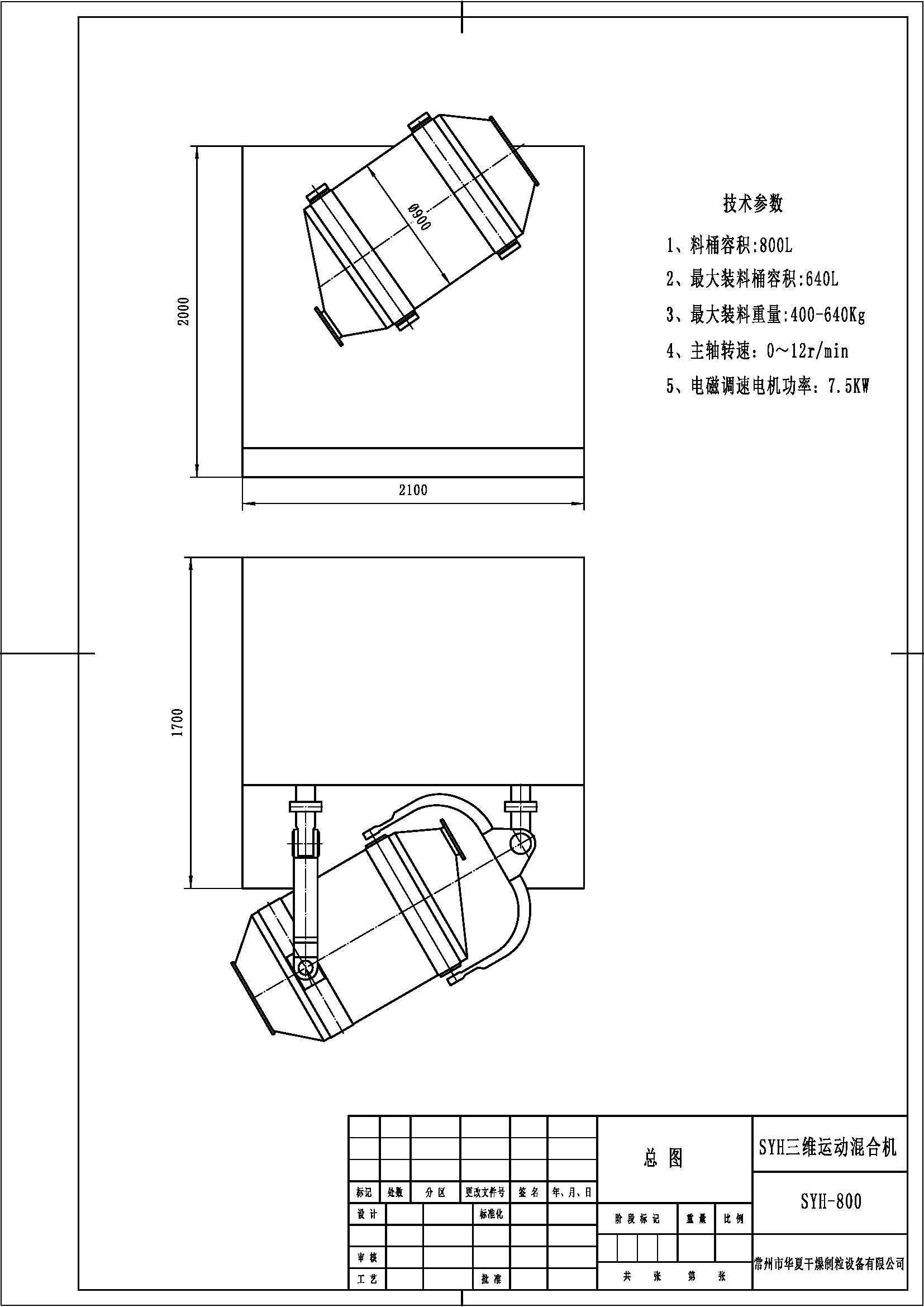

Three-dimensional Mixer

(CE Approved)

Uses and features

*SYH series three-dimensional motion mixer is a high-efficiency mixing device, which can be used for high uniformity mixing of powder and granular materials in the handicrafts of pharmaceutical, food, chemical, light industry, machinery, electronics, mining and metallurgy, defense industry, scientific research and other enterprises.

* The material has no centrifugal force in the mixing process, no specific gravity segregation and delamination, accumulation phenomenon, each component can be evenly mixed under the weight ratio of the suspension beads, the mixing rate is over 99%.

* High loading coefficient, up to 80% (ordinary mixer is only about 40%) and short mixing time, is an ideal product in various mixers.

* The equipment structure is compact, the transmission part adopts stepless speed regulation (frequency conversion or electromagnetic speed regulation), and the operation is very convenient.

* The barrel is circularly transitioned throughout, and is precision-polished to meet GMP requirements.

working principle

The mixing bucket of SYH series three-dimensional mixer is suspended on the ends of the main and driven shafts by two Y-joints, and the two universal joints perform complex motions such as translation, rotation and rolling in the space cycle. The material follows the axial, radial and circumferential three-dimensional composite motion in the cylinder. The various materials in the cylinder flow, diffuse, and dove with each other, and finally become uniform.

4.Technical parameter

Model |

SYH-1 |

SYH-5 |

SYH-15 |

SYH-50 |

SYH-100 |

SYH-200 |

SYH-400 |

SYH-600 |

SYH-800 |

SYH-1000 |

SYH-1200 |

SYH-1500 |

|

Volume of Drum(L) |

1 |

5 |

15 |

50 |

100 |

200 |

400 |

600 |

800 |

1000 |

1200 |

1500 |

|

Maximum Loading Volume (L) |

0.8 |

4 |

12 |

40 |

80 |

160 |

320 |

480 |

640 |

800 |

960 |

1200 |

|

Maximum Loading Weight'(KG) |

0.5 |

2.4 |

7.5 |

25 |

50 |

100 |

200 |

300 |

400 |

600 |

700 |

900 |

|

Main Shaft Speed (r/MIN) |

0-28 |

0-8 |

|||||||||||

Power (KW) |

0.12 |

0.25 |

0.37 |

1.1 |

1.5 |

2.2 |

4 |

5.5 |

7.5 |

7.5 |

11 |

11 |

|

Mesurement |

L |

500 |

750 |

700 |

1400 |

1700 |

1800 |

2100 |

2400 |

2600 |

2650 |

2950 |

3100 |

W1 |

600 |

650 |

1000 |

1000 |

1200 |

1400 |

1800 |

2200 |

2380 |

2500 |

2650 |

2850 |

|

H |

450 |

450 |

700 |

1200 |

1500 |

1600 |

1950 |

2350 |

2500 |

2600 |

2750 |

3000 |

|

W2 |

500 |

550 |

650 |

850 |

1250 |

1350 |

1650 |

1750 |

2000 |

2100 |

2200 |

2250 |

|

Weight (kg) |

50 |

150 |

200 |

200 |

500 |

800 |

1200 |

1500 |

2000 |

2500 |

3000 |

3500 |

|