Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Mixing & Blending>Automatic lifting hopper mixer (CE)

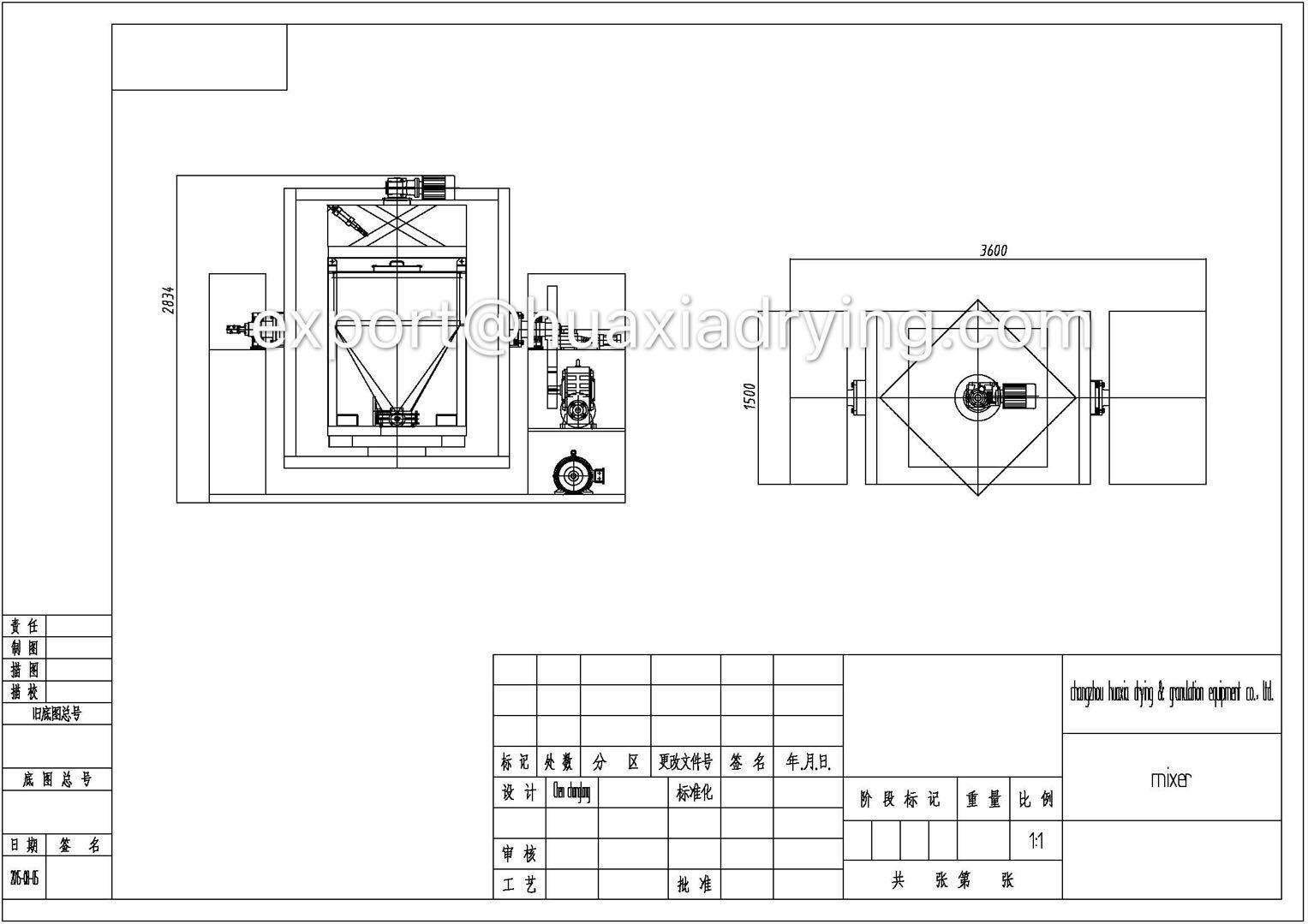

Automatic lifting hopper mixer ( Square Conical Mixer )

(CE Approved)

1. Description :

Automatic lifting hopper mixer can automatically complete the lifting, clamping, mixing, move down actions . With an automatic lifting hopper mixer and a number of different mixing hopper, will be able to meet the large quantities, more varieties of mixed requirements,it is the ideal mixture of pharmaceutical industry ,It also widely used in the pharmaceutical, chemical, food and other industries .

2. Features:

1.Use PLC and frequency inverter to achieve the program control, with a smooth transmission, reliable structure, large amount of mixing, use square cone hopper rotary around the Symmetry axis ,the material in the hopper with asymmetric, multi- Movement, the rotor (mixing hopper) and the rotary axis at an angle of 30 °, the material in the mixing hopper turing with the rotating body, and material do tangential movement on the container wall, resulting in a strong flip and high-speed tangential movement, so as to achieve The best mixing effect.

2.Set the infrared safety device and anti-misoperation device out of the butterfly valve to ensure production safety. Materials can be in the same container through a different block, do not need frequent transfer, feeding and other procedures. Effectively control dust and cross pollution, reduce material loss, control material stratification, optimize the production process, fully meet the GMP requirements of pharmaceutical production

3, with big storage capacity for the parameter, can store 20 different materials (or the same kind of material at different stages of production) process parameters, you can call different process directly .

4.

use stable performance, reliable infrared photoelectric sensor as one of the local safety protection device, effectively protect the staff safety when he operate the equipment .

4、技术参数Technical parameter

Model |

SQM--600 |

SQM-800 |

SQM-1000 |

SQM-1200 |

SQM-1500 |

SQM-1800 |

SQM-2000 |

Volume |

600 |

800 |

1000 |

1200 |

1500 |

1800 |

2000 |

Loading Rate |

0.5~0.8 |

0.5~0.8 |

0.5~0.8 |

0.5~0.8 |

0.5~0.8 |

0.5~0.75 |

0.5~0.75 |

Power ( KW ) |

4 |

5.5 |

5.5 |

5.5 |

5.5 |

7.5 |

7.5 |

Rotating height( mm ) |

2400 |

2900 |

3000 |

3150 |

3300 |

3500 |

3700 |

measurement (mm) |

3000 × 1970 × 2300 |

3000 × 1970 × 2460 |

3400 × 2150 × 2520 |

3400 × 2150 × 2680 |

3400 × 2150 × 2900 |

3550 × 2250 × 3100 |

3550 × 2250 × 3400 |

Weight (t) |

1.8 |

2 |

2.4 |

2.8 |

3.2 |

3.6 |

4 |