Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Drying & Coating>Vibrating Fluidized Bed Dryer (CE)

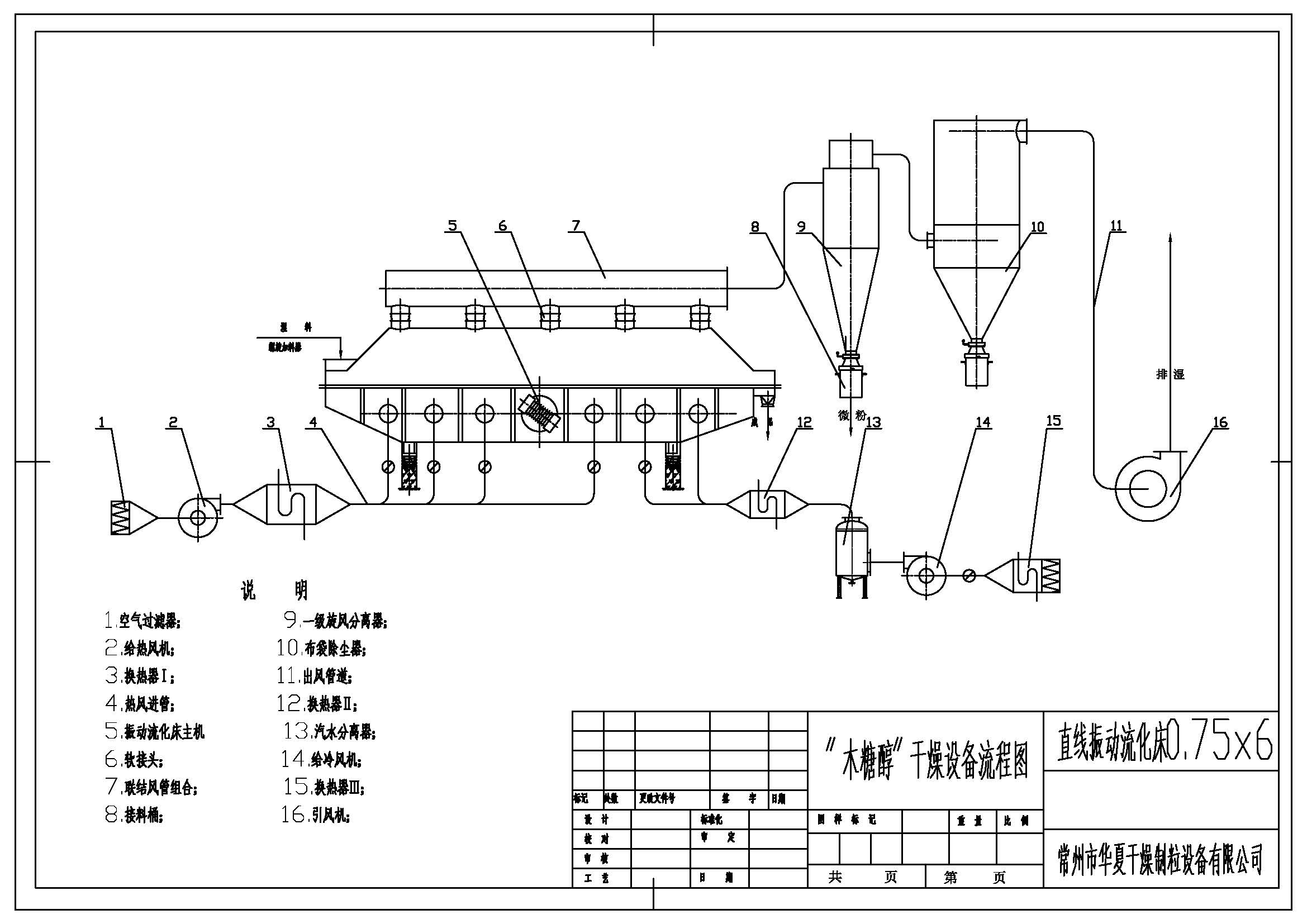

Vibrating Fluidized Bed Drying Equipment

(CE Approved)

1.Principles

Raw material is fed into the machine from the inlet and moves forward continuously along the level of fluidized-bed under the action of vibration. The hot air passes through fluidized-bed and carries out heat exchange with humid raw material. Then the damp air is exhausted out through cyclone separator and dust extractor and the dry raw material is discharged through discharge outlet.

2.Scope of application

◆ Pharmaceutical and chemical industries: all kinds of press tablet and granule, boric acid, borax, dihydroxybenzene,malicacid, maleic acid and so on;

◆ Foodstuff and construction material industries: less,monosodium glutamate, edible sugar, edible salt, mine residue,Bean, seeds and so on;

◆ It can also be used for raw materials to add damp or cooling and so on.

3.Featurs

◆ Raw material is heated evenly and heat exchange is fully and dry capacity is high. Compared with ordinary dryer, the energy can be saved about 30%.

◆ The vibration is created by motor. It is stable in operation and convenient in maintenance, with low noise and long life;

◆ The fluidized state is stable and no dead angle and phenomenon of being broken out;

◆ It is good in adjustment and wide in application.

◆ There is little damage to the surface of raw materials. The equipment can be used for drying raw materials that are easily broken. The drying effect will not be affect ed even if raw materials are anomalous shaped; It can efficiently prevent the cross pollution between raw material and air because the equipment adapts fully closed structure. The environment of operation is clean.

4.Technical parameter

Model |

Area of fluidize-bed (m2) |

Temperature o f inlet air ( ℃ ) |

Temperature of outlet air ( ℃ ) |

Capacity to evaporate vapor/moisture (Kg/h) |

Vibration motor |

|

Model |

Power(Kw) |

|||||

GZQ3 ×0.30 |

0.9 |

70~140 |

40~70 |

20~35 |

ZDS31-6 |

0.8 ×2 |

GZQ4.5 ×0.30 |

1.35 |

70~140 |

40~70 |

35~50 |

ZDS32-6 |

0.8 ×2 |

GZQ4.5 ×0.45 |

2.025 |

70~140 |

40~70 |

50~70 |

ZDS32-6 |

1.1 ×2 |

GZQ4.5 ×0.60 |

2.7 |

70~140 |

40~70 |

70~90 |

ZDS41-6 |

1.1 ×2 |

GZQ6 ×0.45 |

2.7 |

70~140 |

40~70 |

80~100 |

ZDS41-6 |

1.5 ×2 |

GZQ6 ×0.60 |

3.6 |

70~140 |

40~70 |

100~130 |

ZDS42-6 |

1.5 ×2 |

GZQ6 ×0.75 |

4.5 |

70~140 |

40~70 |

120~140 |

ZDS42-6 |

2.2 ×2 |

GZQ6 ×0.90 |

5.4 |

70~140 |

40~70 |

140~170 |

ZDS42-6 |

2.2 ×2 |

GZQ7.5 ×6.0 |

4.5 |

70~140 |

40~70 |

130~150 |

ZDS51-6 |

2.2 ×2 |

GZQ7.5 ×0.75 |

5.625 |

70~140 |

40~70 |

150~180 |

ZDS51-6 |

3.0 ×2 |

GZQ7.5 ×0.90 |

6.75 |

70~140 |

40~70 |

160~210 |

ZDS51-6 |

3.0 ×2 |

GZQ7.5 ×1.2 |

9 |

70~140 |

40~70 |

200~260 |

ZDS51-6 |

3.0 ×2 |