Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Drying & Coating>Single Arm Spiral Conical Vacuum Drying Equipment(CE)

Single Arm Spiral Conical Vacuum Drying Equipment

(CE Approved)

1. Description :

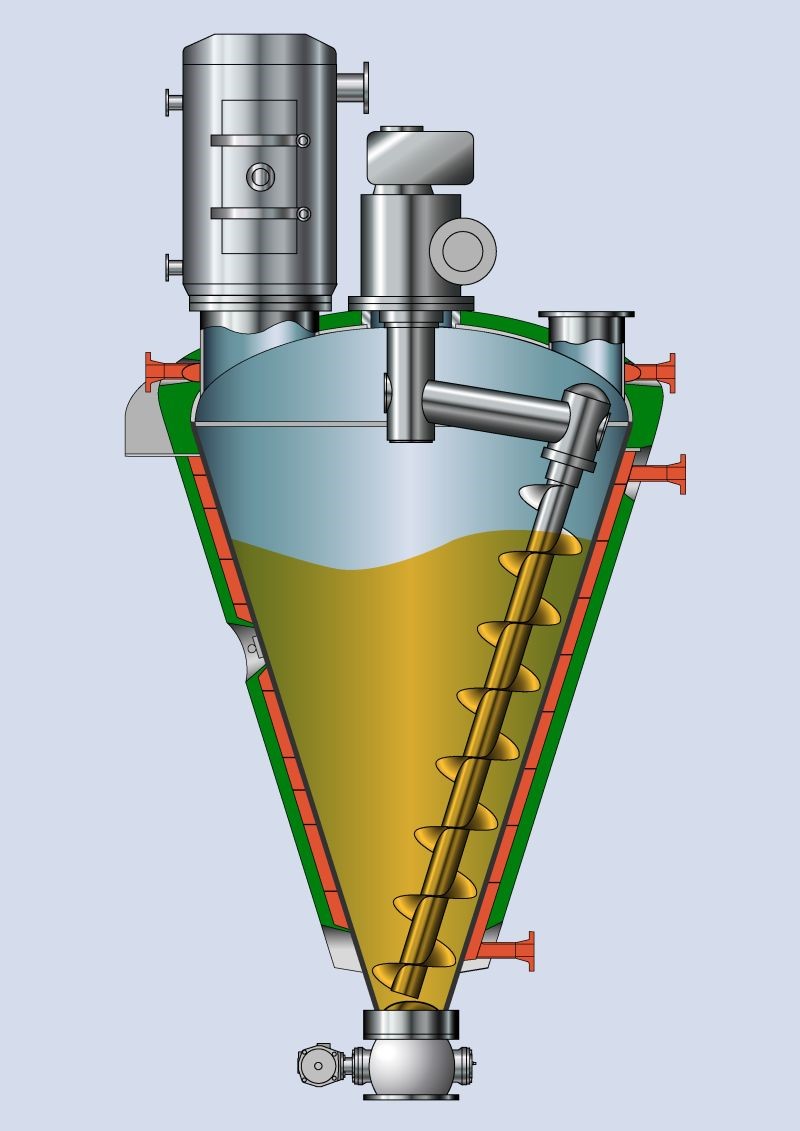

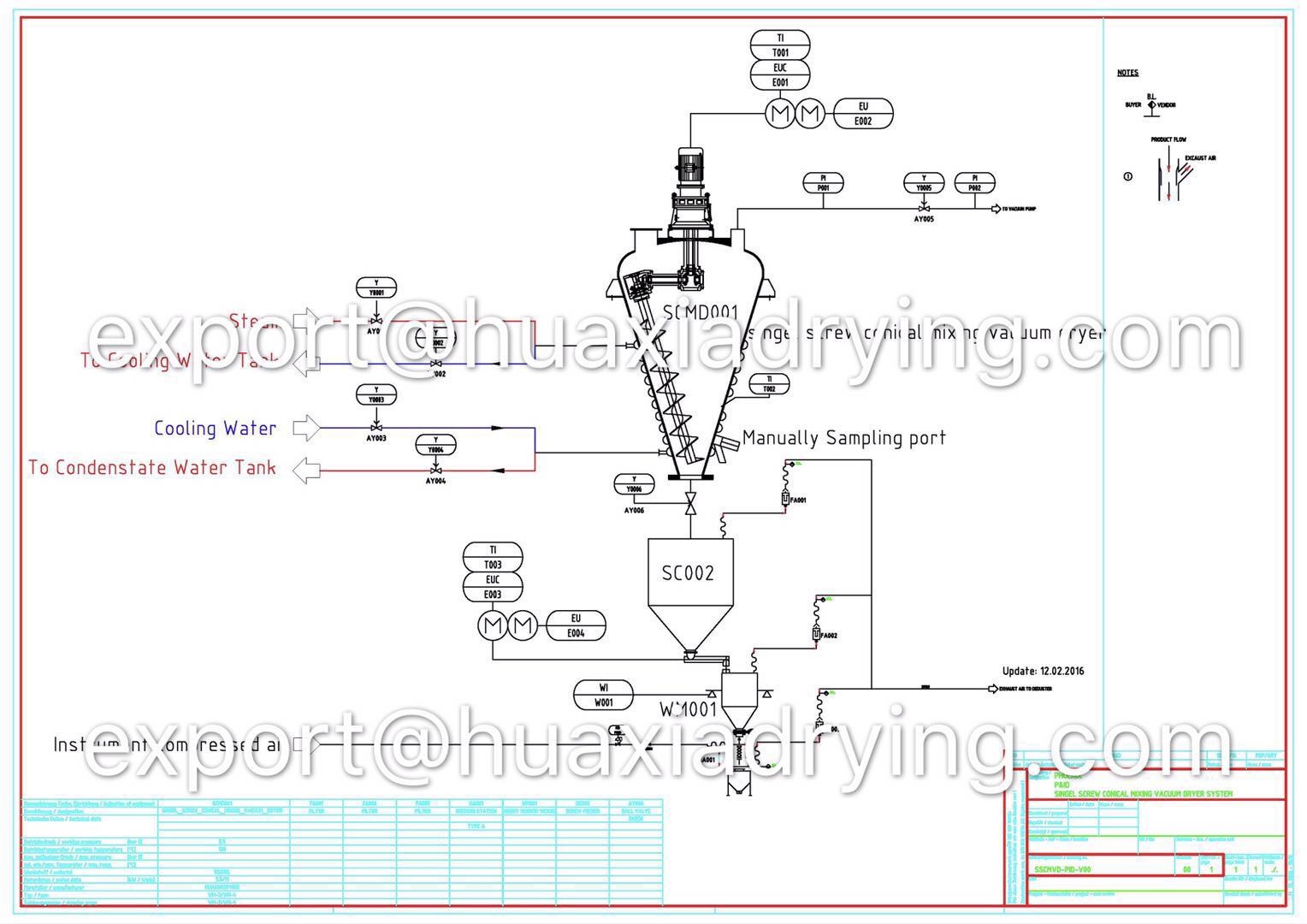

Single-arm spiral vacuum dryer is a jacket conduction heating batch mode drying equipment, it is widely used vacuum drying equipment in the European and American countries in the pharmaceutical production, the drying equipment with vacuum drying and mixing double function. After the material is added from the top inlet , the feed inlet is closed, the heating system is started, the vacuum system, the stirring system, the single-arm screw is rotated at the same time along the circumferential direction of the inner wall of the cone. The material moves upwards under the spiral lifting, The inner wall of the cone and the material in full contact with the material, the material and the internal wetting temperature increases, in the vacuum state, the boiling point of moisture decreased , evaporation of the moisture been taken out by vacuum under low temperature , then complete the drying process.

2. Featurs:

Single-arm spiral conical vacuum dryer suit for use in the GMP workshop, the machine has a high dry & mixing efficiency ,the capacity is 3-4 times of double cone vacuum dryer ,it can work under the condition of 10% -100% filling rate ,screw mixing can achieve a higher mixing accuracy with the screw rotating and screw arm rotating along the conical circumferential direction , feed in few material into a large quantity of other material can also be well distributed , by its different low-speed mixing characteristics, even for dry processing sensitive products, It will not be damaged, the required drive power is relatively low. And the dryer directly connected to the filter can retain the dust in the processing area, the machine uses inflatable sealed dome valve, discharge thoroughly, convenient, excellent vacuum, pressure sealing performance, no dead ends, easy to clean design, performance Stable, long service life, able to handle products without loss.

Full Cantilever Conical Stirring Screw

Fully enclosed system

Product mixing under slow speed , well distributed

Use a variety of materials and techniques to achieve a safe and reliable seal

Low mechanical shear force

Short Drying time , low energy consumption

High precision, good mixing effect, strong renewable

No pollution gas leaks

Applicable to the various products, widely used

Adjust the speed according to product characteristics

Can be flexible load rate (10-100%), no affect on product quality

Use the heating screw shaft to shorten the drying time

Solid discharge and cleaning fluid discharge without residue

To ensure the safety of products, operators and production processes

CIP is simple and efficient, thoroughly discharg

Can be used for a variety of products processing

3. Scope of application:

Flowable products: powder, particles, crystals and other

dangerous material

For mechanical handling and high temperature sensitive products

Flammable and explosive powders

Oxidized products are easily decomposed

4.Technical parameter

Model |

50L |

100L |

200L |

500L |

1000L |

1500L |

2000L |

3000L |

4000L |

5000L |

Volume L |

50 |

100 |

200 |

500 |

1000 |

1500 |

2000 |

3000 |

4000 |

5000 |

Inner Diameter mm |

500 |

620 |

800 |

1100 |

1350 |

1550 |

1700 |

1950 |

2150 |

2300 |

Power KW |

1.5 |

1.5 |

2.2 |

3.7 |

5.5 |

5.5 |

7.5 |

11 |

22 |

22 |

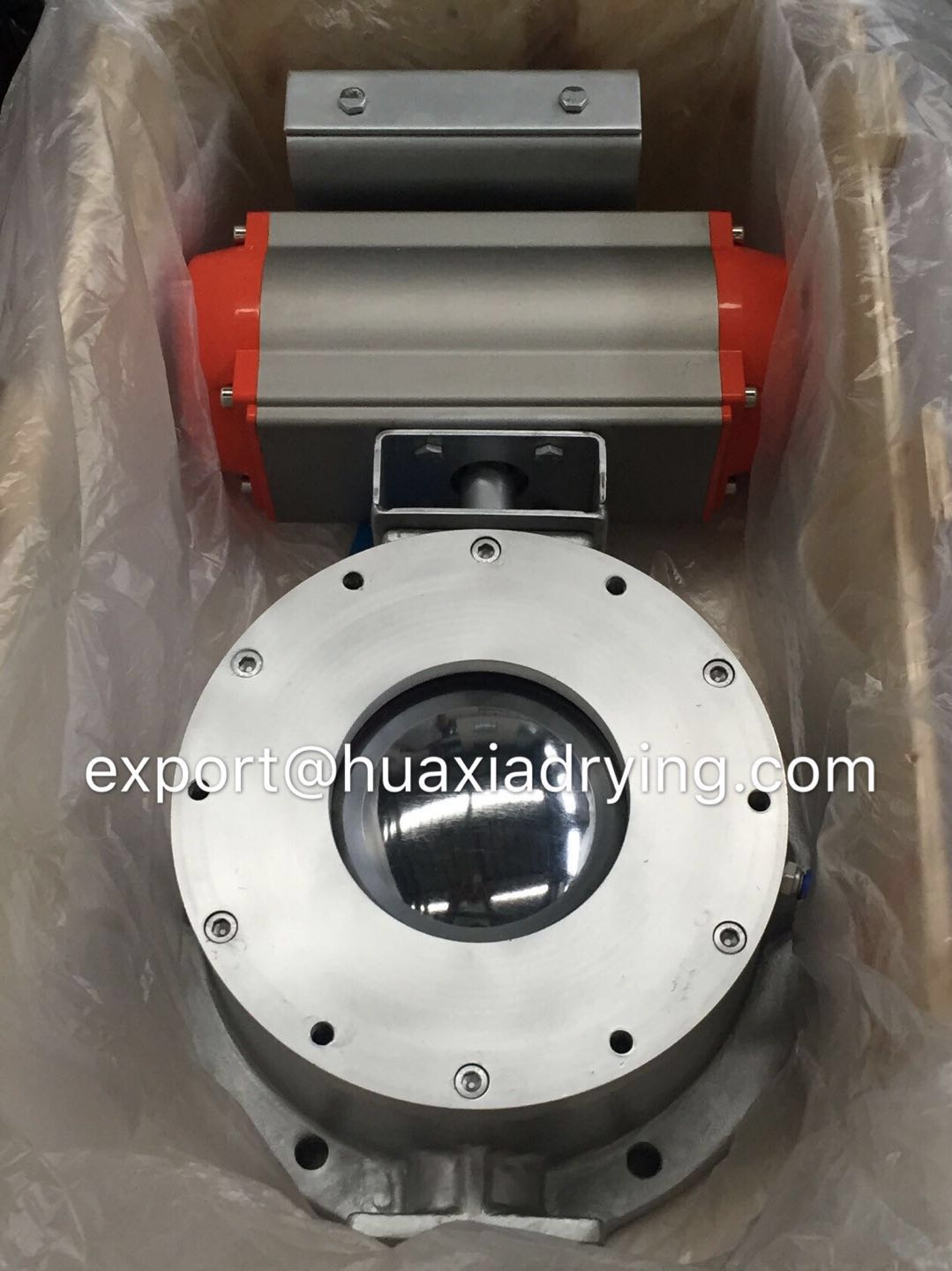

5.Discharge valve(Inflatable dome valve)