Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Drying & Evapration >Evaprator

1.Descriptions

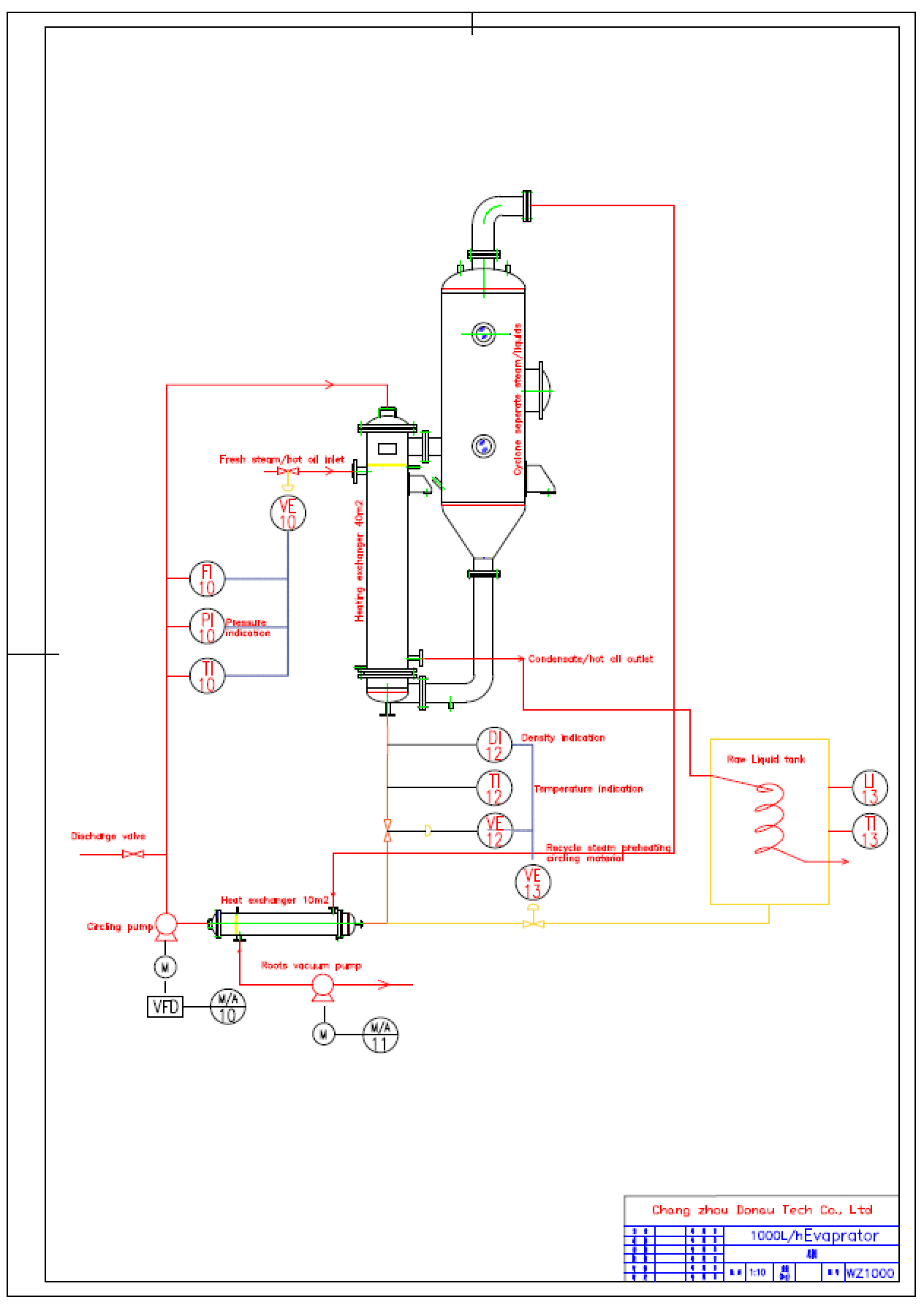

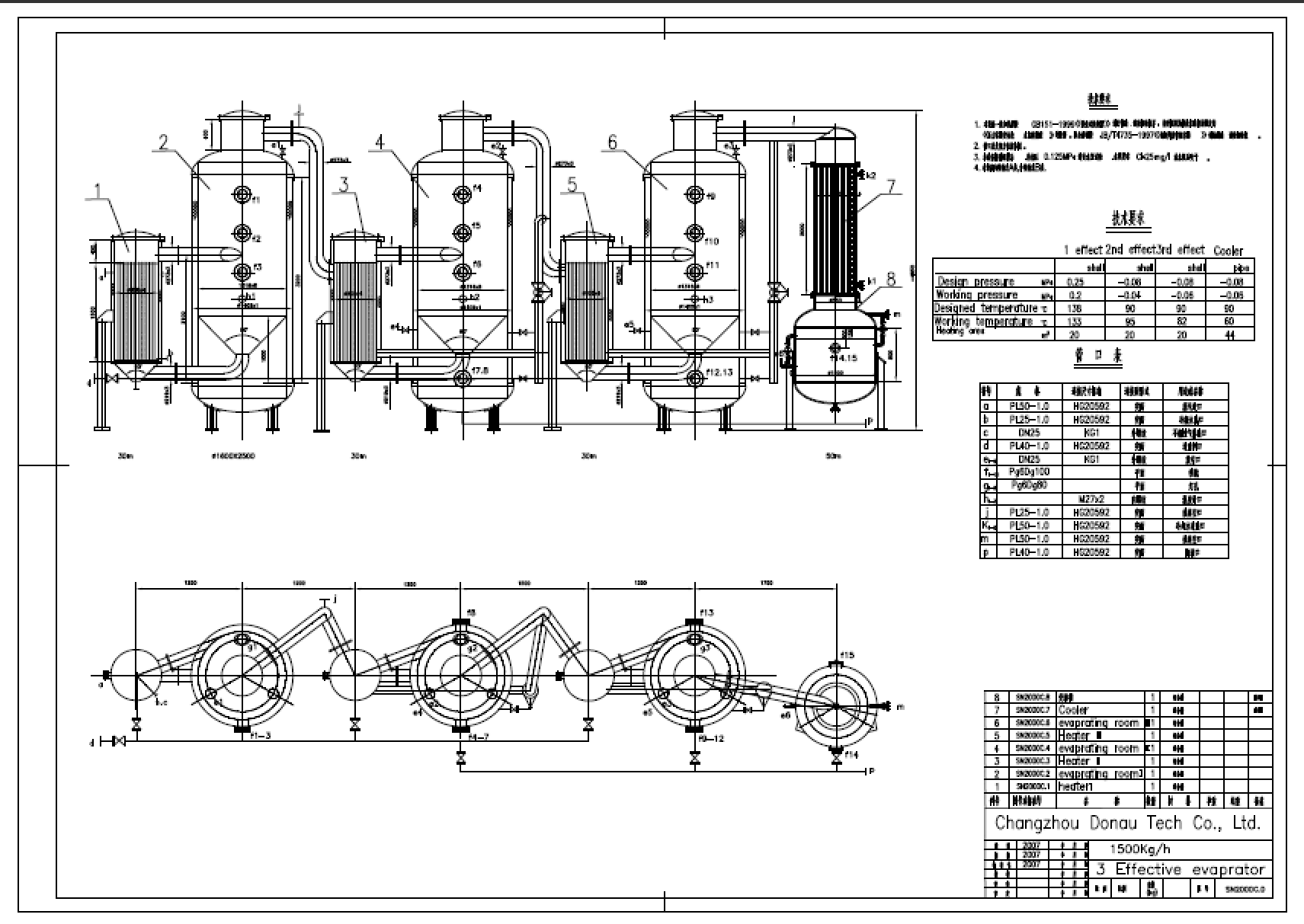

There are many kinds of evaporators, such as single-effect falling film evaporator, 2-effect falling film evaporator, multi-effect falling film evaporator, scraper evaporator and so on.

Single-effect falling film evaporator equipment is used for liquid low-temperature evaporation in food, chemical, pharmaceutical and other industries. It can continuously feed and discharge. The material has short heating time and low evaporation temperature. The liquid can reach the required concentration requirement once in the equipment. . It has little effect on the color, flavor and nutrients of the product, especially for the evaporation of heat sensitive materials such as milk.

The two-effect falling film evaporator process is widely used in the production of pharmaceutical, food, biological, etc. For example, in the production of traditional Chinese medicine, the extract is concentrated by evaporation to obtain a concentrate or a flow extract, and as in the antibiotic production, the evaporation operation is used. The fermentation filtrate, the resin eluate, and the various extracts were concentrated.

The multi-effect falling film evaporator is widely used for the concentration of aqueous solutions such as glucose, starch sugar, oligosaccharide, sucrose, sorbitol, fresh milk, juice, vitamin C, maltodextrin and the like. It can also be applied to waste liquid treatment in industries such as MSG, alcohol and fishmeal.

The equipment is continuously operated under vacuum and low temperature conditions, and has high evaporation capacity, energy saving, low operating cost, and can maintain the original color, fragrance, taste and composition of the material to be processed. It is widely used in many industries such as food, medicine, food deep processing, beverage, light industry, environmental protection, and chemical industry.

2.Features

High production efficiency and large evaporation.

The energy saving effect is remarkable.

The evaporation temperature is low under vacuum, and some of the secondary steam is re-inhaled into the next effect heater by the jet type heat pump, and the heat is fully utilized, and the evaporation temperature is relatively low.

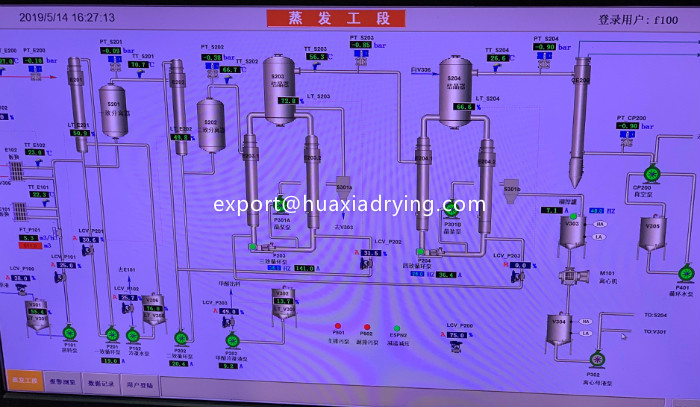

The system is fully automatic and runs smoothly.

Item |

Capacity(H2O)Kg/h |

Heating area |

Cooling area |

Temperature ℃ |

Vacuum MPa |

Measurement |

||||

1st Efficiency |

2nd |

3rd |

1st |

2nd |

3rd |

|||||

WZ-Ⅲ500 |

500 |

15 |

7.5 |

85 |

75 |

60 |

0.02 |

0.06 |

0.08 |

5.9X1.25.X2.49 |

WZ-Ⅲ1000 |

1000 |

30 |

15 |

85 |

75 |

60 |

0.02 |

0.06 |

0.08 |

6.8X1.45X3.5 |

WZ-Ⅲ2000 |

2000 |

60 |

30 |

85 |

75 |

60 |

0.02 |

0.06 |

0.08 |

9.3X1.8X4.2 |

3.Technical Parameters

To be confirmed by raw material charactor & technical flow .