Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>Drying & Coating>Pneumatic Conveyor Drying Equipment(CE)

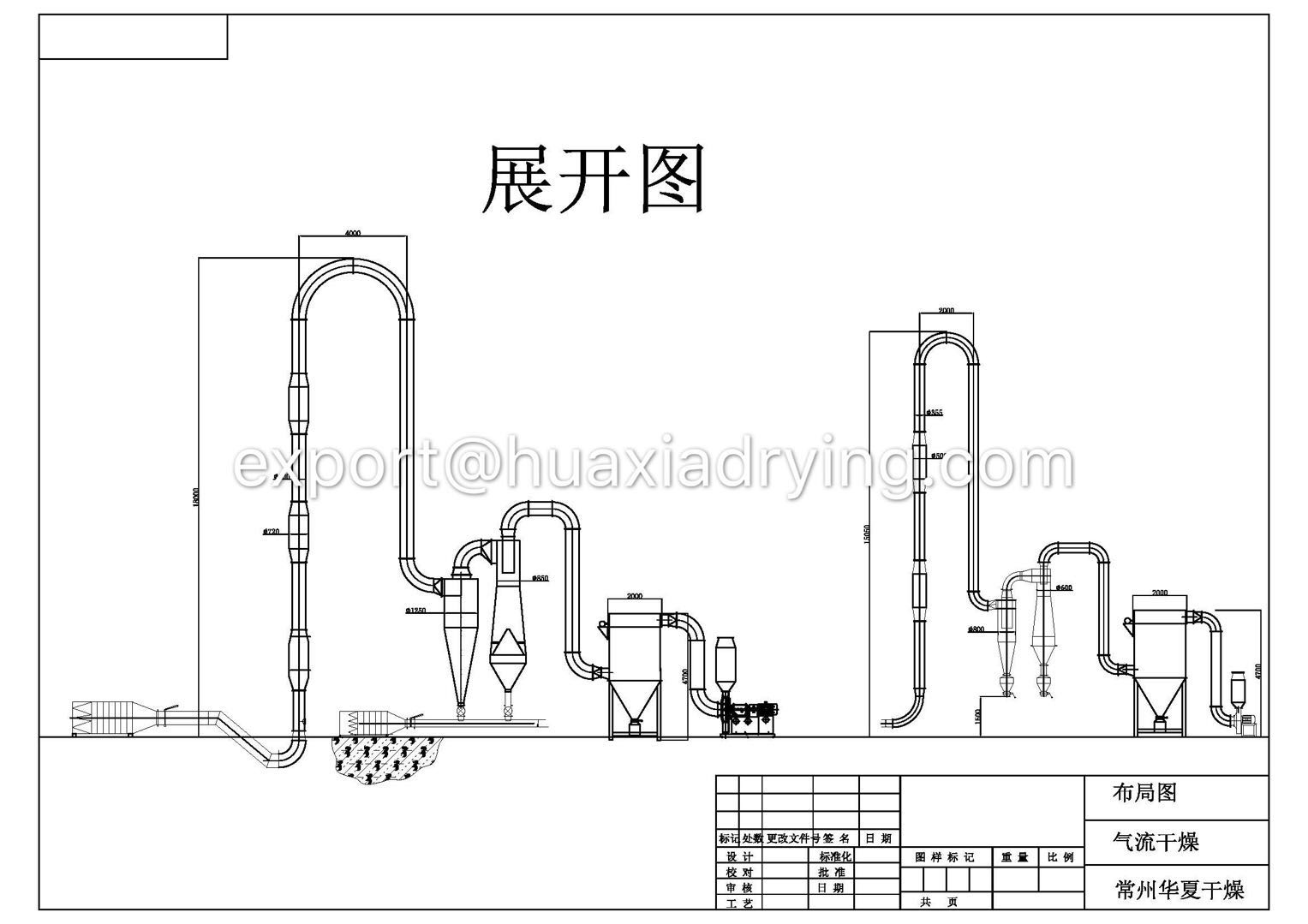

Pneumatic Conveyor Drying Equipment

(CE Approved)

1. Description :

Pneumatic dryer, also known as instantaneous drying, it is exchange heat during the conveyor of wet material by high temperature air , evaporate the moisture and separate it by cyclone & de-duster.

2. Featurs:

◆ High efficiency , low investment of equipment : pneumatic conveyor drying equipment handling large capacity , evaporation water capacity from 50kg / h-1500kg / h, and equipment with small size, low investment .

◆ high automatical control , good product quality: all material inside the pipeline , the drying time is very short (only 0.5-2 seconds), it can be automated, the product does not contact with the outside world, pollution, good quality.

◆ complete sets of equipment supply, heat source selectable : the basic type by the air filter, heater, feeder, drying tube, fan, cyclone separation, dust collector or some other auxiliary equipment as needed.

◆ In the heating mode selection, the pneumatic conveyor drying equipment has a greater adaptability, the user can choose steam, electricity, hot air furnace heating according to the conditions of the site , also can according to the material heat temperature (or hot air temperature) : 150 ℃ , choose steam heating; 200 ℃, choose electric heating (or steam heating, electrical compensation or heating oil heating); 300 ℃, choose the coal-fired hot air furnace; 600 ℃, choose the fuel hot air furnace.

3. Scope of application:

The equipment is widely used in food, chemical, pharmaceutical, building materials and other industries powder, granular material drying. Has been used in the series of dried products are: starch, glucose, fish meal, sugar, salt, lees, feed, gluten, plastic resin, coal, dyes and so on.

Ammonia ketone, ABC intermediates, ABS resin, ASC, white carbon black, benzene tea pyrazolone, tea meal, oxalic acid catalyst, accelerator m, dm, catalyst, precipitated charcoal, p-acetylglenzenesulfonamide, Amino acid salicylic acid, digitot, terephthalic acid, diethylanilinium, titanium dioxide, activated carbon, sodium fluorosilicate, fluorite, by-product ammonium sulfate, silica gel powder, synthetic resin, calcium sulfonate, poly Acrylic resin, chlortetracycline, sodium pyrosilicate, coffee dextrose, oral glucose, sodium sulfate, sulfide ore, phosphate rock, blue BB, PVC, molten phosphate, tetracycline, iron trioxide, calcium carbonate, Ore, copper, potato powder, tail coal, stearate, corn protein, pharmaceuticals, pharmaceuticals, iron oxide, rosacea and so on.

Vinyl acetate and polyethylene copolymer, cellulose acetate floc, catalyst, CMC, CT-1 resin, calcined gypsum, electrolytic manganese dioxide, ammonium anthraquinone sulfonate, fluorite, diatomaceous earth, silica gel catalyst, bone meal Potassium sulfate, aluminum sulfate, sodium sulfate, calcium phosphate, phosphoric acid esterified starch, dyestuffs, dyestuffs, Calcium citrate, slime, clay, clay, aluminum hydroxide, barium hydroxide, calcium lactate, food, cyanuric acid, gypsum pulp, lime, biological products, carbon black, calcium carbonate slurry, sludge slag, organic Chemicals Aluminum stearate, iron oxide, organic fuels, corn gluten feed, wet mud, mica powder, pharmaceuticals, pigments, potassium dichromate pulp, lees residue

4.Technical parameter

4.1.FG Series

Model |

moisture to be evaporated (Kg.h) |

|

|

efficiency(%) |

FG0.25 |

113 |

11 |

3.5*2.5 |

>70 |

FG0.5 |

225 |

18.5 |

7*5 |

>70 |

FG0.9 |

450 |

30 |

7*6.5 |

>70 |

FG1.5 |

675 |

50 |

8*7 |

>70 |

FG2.0 |

900 |

75 |

11*7 |

>70 |

FG2.5 |

1125 |

90 |

12*8 |

>70 |

FG3.0 |

1150 |

110 |

14*10 |

>70 |

FG3.5 |

1491 |

110 |

14*10 |

>70 |

4.2.QG Series

Model |

moisture to be evaporated (Kg.h) |

power(Kw) |

area to occupied (m2) |

height(M) |

QG 50 |

50 |

7 |

20 |

14 |

QG 100 |

100 |

13 |

32 |

14 |

QG 200* |

200 |

21 |

40 |

15 |

QG 250 |

250 |

24 |

64 |

15 |

QG 500 |

500 |

43 |

96 |

18 |

QG 1000* |

1000 |

100 |

120 |

18 |

QG 1500* |

1500 |

150 |

200 |

20 |

4.3.JG Series

| Model | moisture to be evaporated (Kg.h) |

power(Kw) |

area to occupied (m2) |

height(M) |

JG 50 |

50 |

10 |

20 |

9 |

JG 100 |

100 |

20 |

32 |

11 |

JG 200* |

200 |

31 |

40 |

11 |

JG 250 |

250 |

32 |

64 |

13 |

JG 500 |

500 |

54 |

96 |

13 |

JG 1000* |

1000 |

135 |

120 |

15 |

JG 1500* |

1500 |

175 |

200 |

16 |