Magnetic industry ferrite granulator

Button battery powder granulator

Tungsten, cobalt, manganese granulators

Lithium iron phosphate battery granulator

Disinfectant industry granulator, dryer

Chemical industry dry powder granulator

Plastic rubber flame retardant granulator

CURRENT POSITION:HOME PAGE>PRODUCTION LIST>DRYING & EVAPRATION>VACUUM BELT DRYER (CE)

Energy Saving Drying Equipment --Vacuum Belt Dryer ( Can be CE&PED certificated )

Vacuum belt continuous dryer

1.Description

Vacuum continuous solid-state dryer with 3-11 layers in the vacuum container. Through the continuous solid feeder and distributor, the raw materials needed by customers can be continuously fed under vacuum conditions, and the uniform cloth can be placed on the conveyor. On the drying belt, as the material is continuously turned during the drying process, the evaporation speed and time are accelerated, and the uniformity of the product during the drying process is ensured. The drying temperature is adjustable from 30°C to 150°C, and the material goes from the dryer to the dryer. The output is adjustable after about 20-80 minutes. After the dried product needs to be crushed, it can be crushed under vacuum conditions to avoid flying dust, increasing product yield and solving problems such as pollution. The dried product is continuously discharged through the vacuum continuous feeder and the vacuum receiver. At the same time, the organic solvent can be recovered, the environmental protection problem is solved, and the solvent recovery benefit is increased.

2.Drying principle

According to the size of the customer's production capacity, the 3-11 layer conveyor belt is designed and arranged in the vacuum container. Through continuous solid feeders and distributors, the raw materials needed by customers can be continuously fed under vacuum conditions, and the uniform cloth can be placed dry. With the belt, as the material is continuously turned during the drying process, the evaporation speed and time are accelerated, and at the same time, the uniformity of the product during the drying process is ensured. The drying temperature is adjustable at 30-150° C., and the material goes from the dryer to the dryer. The material is adjustable in about 20-80 minutes. After the dried product needs to be crushed, it can be crushed under vacuum conditions to avoid flying dust, increasing product yield and solving problems such as pollution. The dried product is continuously discharged through the vacuum continuous feeder and the vacuum receiver. At the same time, the organic solvent can be recovered, the environmental protection problem is solved, and the solvent recovery benefit is increased.

3.Scope of application

◆Chinese medicine, western medicine, food, chemical industry, etc.

◆ Various solids, crystals, granules, powders, pills, fruits and other raw materials

◆Easily oxidized, explosive, strong stimulation, highly toxic materials

◆Products requiring recycling of various solvents

Features

◆Continuous feeding continuous discharge under vacuum conditions

◆To achieve automation of drying process, continuous, pipeline

◆ Drying process temperature is adjustable at 30-150°C

◆The operating cost is one-third of the traditional drying process

◆Product yield reaches above 99%

◆Adjustable drying time 20-80 minutes

◆ greatly reduce labor costs

◆ PLC automatic control system

◆ Reduced the complexity of the process of drying caused by product contamination

◆To achieve solvent recovery during product drying

◆ Online automatic cleaning, in line with GMP requirements

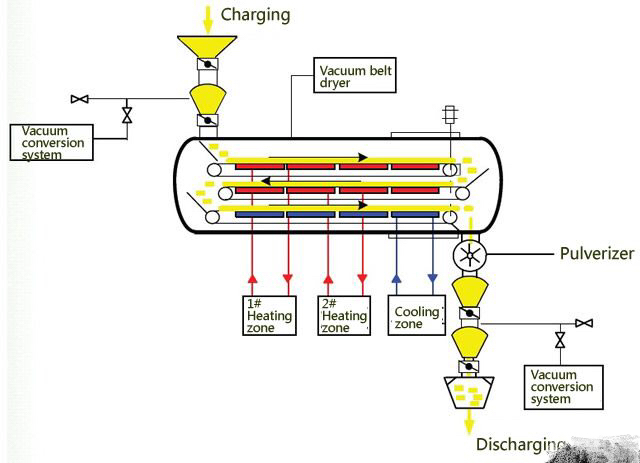

4.schematic diagram

5.Technical Parameter

Parameter\Model |

VBD6.5-3 |

VBD15-3 |

VBD30-5 |

VBD50-5 |

VBD80-5 |

VBD100-7 |

VBD120-7 |

VBD160-7 |

VBD200-11 |

VBD220-11 |

Heating Area |

6.5 |

15 |

30 |

50 |

80 |

100 |

120 |

160 |

200 |

220 |

Effective moisture evaporation(Kg/h) |

5~10 |

10~20 |

25~35 |

40~60 |

70~90 |

90~120 |

110~130 |

150~180 |

180~210 |

210~230 |

Number of heat exchange plates |

3 |

3 |

5 |

5 |

5 |

7 |

7 |

7 |

11 |

11 |

Drying temperature range |

40~180 |

|||||||||

Configuration of Heating and cooling area |

2/1 |

2/1 |

4/1 |

4/1 |

4/1 |

6/1 |

6/1 |

8/1 |

10/1 |

10/1 |

Raw Moisture content |

20~30 |

|||||||||

Final moisture content |

≤1~4 |

|||||||||

Heating media |

热水Hot Water、蒸汽Steam、导热油Hot oil |

|||||||||

mesurements(L/W/H)mm |

6500 /1200 /2200 |

6500 /1900 /2500 |

9500 /1900 /2500 |

12000 /2200 /2800 |

12000 /2600 /3000 |

12500 /2600 /3000 |

17500 /2600 /3000 |

17500 /3000 /3200 |

17500 /3200 /3200 |

19500 /3200 /3200 |

Total power |

18 |

24 |

30 |

34 |

36 |

40 |

45 |

48 |

50 |

58 |

Washing working pressure(MPa) |

0.5~1 |

|||||||||

Capacity |

30~60 |

60~100 |

100~150 |

150~220 |

200~300 |

250~350 |

300~400 |

350~450 |

400~600 |

500~800 |

Remark |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|