当前位置:主页>产品列表>干燥蒸发设备>高速混合机(湿法混合造粒机)(CE)

High speed mixer(Wet material mix granulator)(CE)

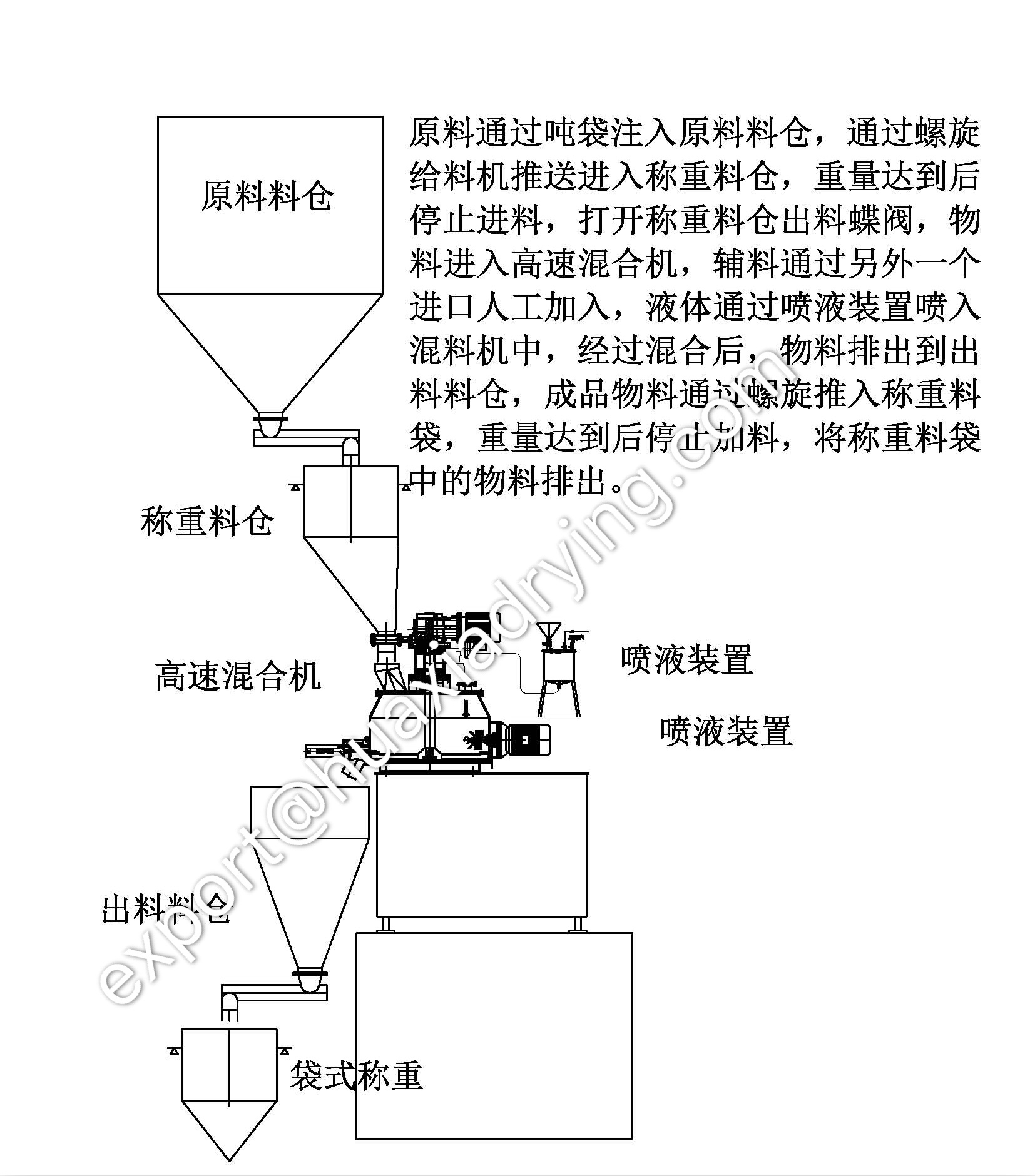

高速混合机 (高速混合喷液造粒 )

(CE Approved)

1. 概述( Description ):

高速Wet material mix granulator在化工、医药、食品、冶金、电池领域广泛使用,可用于粉体与粉体的混合、粉体添加少量液体混合、粉体与颗粒的混合等工艺。

每批次处理能力100L ~ 600L

每批次处理物料50Kg~ 250Kg

所用混合时间在3~60分钟

设备材质可为316L、304、钛合金

上驱动式高速Wet material mix granulator可以避免物料掉入轴承的密封位置,导致轴承故障,可以避免润滑液与物料接触, 是GMP的一个好的解决方案。

Horizontal ribbon mixing machine is widely used in the chemical industry, medicine, food, metallurgy ,battary and other fields ,It can be used for powder and powder mixture, the powder to add a small amount of liquid mixing, powder and particle mixing process.

Each batch processing capacity of 100L to 600L

50Kg to 250Kg of material per batch

Mixing time is between 3 and 60 minutes

Equipment material can be 316L, 304, Titanium alloy .

Top drived high speed wet method mixing & granulation equipment can avoid material fall into the seal of bearing , lead to the bearing damaged , also avoid the grease go into the material , it's good solution for GMP requirements .

2. 应用范围(Scope of application):

本机适用于医药、化工、食品、冶金、建材等行业的粉状、粒状物料的混合以及均质化。

This machine is suitable for pharmaceutical, chemical, food, metallurgy, building materials and other industries powder, granular material mixing and homogenization.

4、技术参数Technical parameter

项目Item |

型号Model |

||||||

50 |

150 |

200 |

250 |

300 |

400 |

600 |

|

容积Volume (L) |

50 |

150 |

200 |

250 |

300 |

400 |

600 |

产量Capacity (kg) |

15 |

50 |

80 |

100 |

130 |

200 |

280 |

混合速度Mixing Speed(r.p.m) |

200/400 |

180/270 |

180/270 |

180/270 |

140/220 |

106/155 |

80/120 |

混合功率Mixing Power(kw) |

4/5.5 |

6.5/8 |

9/11 |

9/11 |

13/16 |

18.5/22 |

22/30 |

切割速度Cutting Speed (r.p.m) |

1500/3000 |

1500/3000 |

1500/3000 |

1500/3000 |

1500/3000 |

1500/3000 |

1500/3000 |

切割功率Cutting Power(kw) |

1.3/1.8 |

2.4/3 |

4.5/5.5 |

4.5/5.5 |

4.5/5.5 |

6.5/8 |

9/11 |

压缩空气耗量Compressed Air Consumption(m3/min) |

0.6 |

0.9 |

0.9 |

0.9 |

1.1 |

1.5 |

1.8 |