当前位置:主页>产品列表>干燥蒸发设备>气流干燥机(CE)

气流干燥机(CE)

Pneumatic Conveyor Drying Equipment

(CE Approved)

1. 概述( Description ):

气流干燥又称瞬间干燥 ,是通过高温热气体输送物料过程中进行热交换,蒸发出湿分并分离的一种干燥方式。

Pneumatic dryer, also known as instantaneous drying, it is exchange heat during the conveyor of wet material by high temperature air , evaporate the moisture and separate it by cyclone & de-duster.

2. 特点( Featurs):

◆干燥强度大、设备投资省:气流干燥设备的处理量大,蒸发水份能力从 50kg/h-1500kg/h ,而设备体积小,投资省。

◆ High efficiency , low investment of equipment : pneumatic conveyor drying equipment handling large capacity , evaporation water capacity from 50kg / h-1500kg / h, and equipment with small size, low investment .

◆自动化程度高、产品质量好:气流干燥物料全在管道中进行,干燥时间极短 ( 只有 0.5-2 秒 ), 因此可实现自动化,产品不与外界接触,污染小,质量好。

◆ high automatical control , good product quality: all material inside the pipeline , the drying time is very short (only 0.5-2 seconds), it can be automated, the product does not contact with the outside world, pollution, good quality.

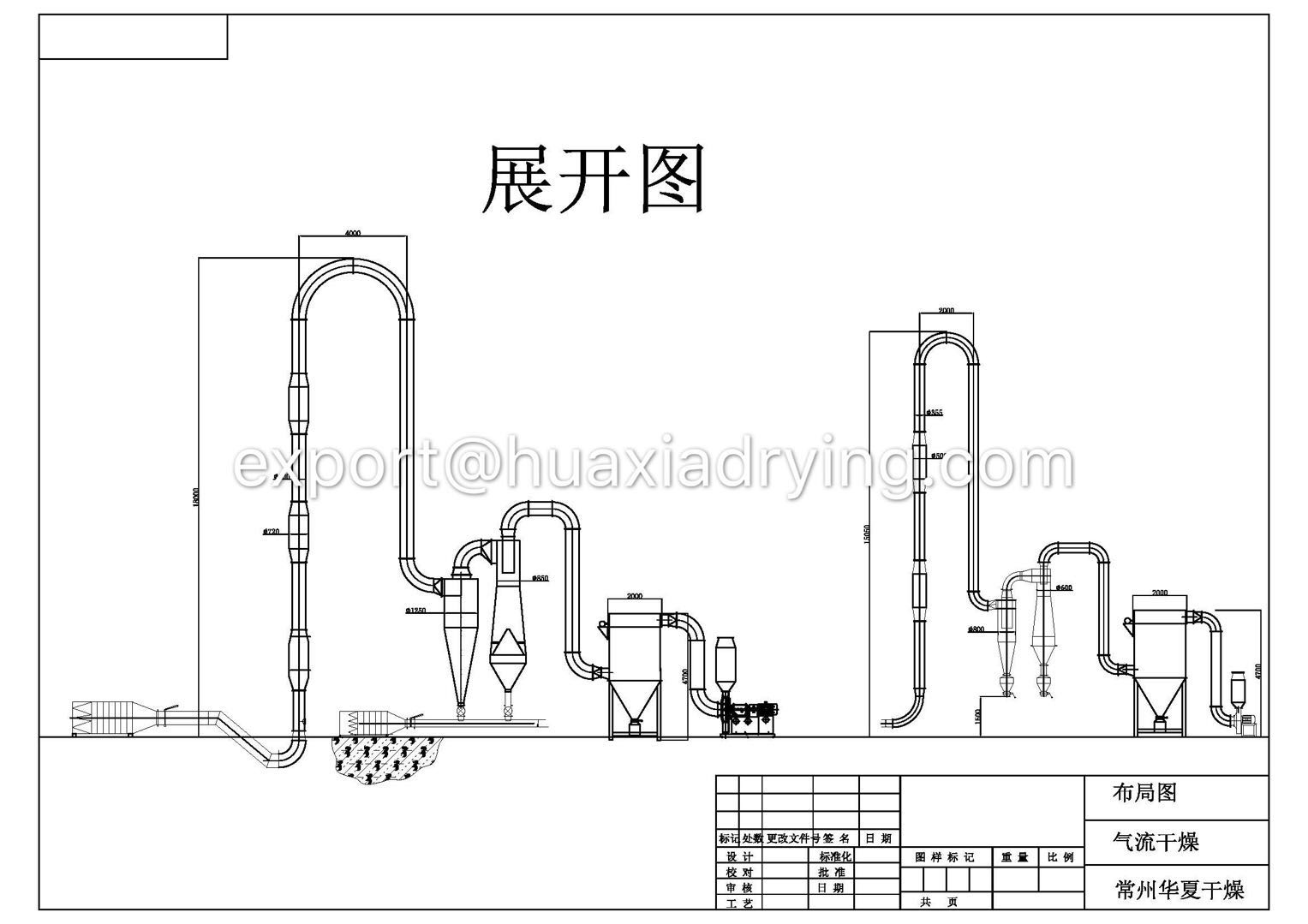

◆设备成套供应、热源自由选择:基本型由空气过滤器 、加热器、加料器、干燥管、风机、旋风分离、除尘器或其他辅助设备。

◆ complete sets of equipment supply, heat source selectable : the basic type by the air filter, heater, feeder, drying tube, fan, cyclone separation, dust collector or some other auxiliary equipment as needed.

◆在加热方式选择上,气流干燥设备有较大的适应性,用户可根据所在地区的条件选用蒸汽、电、热风炉加热 ,同时也可根据物料耐热温度(或热风温度)选择: 150 ℃时,可选用蒸汽加热; 200 ℃时 ,电加热 ( 或蒸汽加热,电补偿或导热油加热 ) ; 300 ℃时,燃煤热风炉; 600 ℃时,燃油热风炉。

◆ In the heating mode selection, the pneumatic conveyor drying equipment has a greater adaptability, the user can choose steam, electricity, hot air furnace heating according to the conditions of the site , also can according to the material heat temperature (or hot air temperature) : 150 ℃ , choose steam heating; 200 ℃, choose electric heating (or steam heating, electrical compensation or heating oil heating); 300 ℃, choose the coal-fired hot air furnace; 600 ℃, choose the fuel hot air furnace.

3. 应用范围(Scope of application):

本设备广泛地用于食品、化工、医药、建材等行业的粉状、颗粒状物料的干燥。已用该系列干燥过的产品有:淀粉、葡萄糖、鱼粉、砂糖、食盐、酒糟、饲料、面筋、塑料树脂、煤粉、染料等。

安眠酮 、 A.B.C 中间体 、 ABS 树脂、 A.S.C 、白碳黑 、苯茶吡唑酮 、茶粕、草酸催化剂、促进剂 m 、 d.m 、触媒 、沉淀炭粉 、对乙酰氮基苯磺酰氨、对氨基水杨酸、哆耳玛托 、对苯二酸、二乙苯铵、二氧化钛 、活性碳、氟硅酸钠 、氟石矿、副产硫铵、硅胶粉末、合成树脂、磺酸钙 , 聚丙烯树脂、金霉素 、焦硅酸钠、糠氯酸咖啡渣、口服葡萄糖、硫酸钠 , 硫化矿 、磷矿粉、兰 BB 、 P.V.C 、熔融磷肥、四环素、三氧化铁、碳酸钙、钛铁矿、铜矿、土豆粉、尾煤、硬脂酸盐、玉米蛋白、药品 、药剂 , 氧化铁、酒渣等。

醋酸乙烯及聚乙烯的共聚物,醋酸纤维絮,催化剂、 CMC 、 CT-1 树脂、煅石膏、电解二氧化锰、蒽醌磺酸铵盐、氟石、硅藻土、硅胶催化剂、骨粉、过氟酸钾磺铵类药物、合成树脂、活性面筋、恬性白土、化学滤饼、金红石型钛白粉、癸二酸、硫酸铜、硫酸铝、硫酸钠、磷酸钙、磷酸酯化淀粉、染料、柠檬酸钙、煤泥、粘土、粘土水泥、氢氧化铝、氢氧化钡、乳酸钙、食品、三聚氰酸、石膏浆、石灰、生物制品、碳黑、碳酸钙浆、污泥渣、有机化学品硬脂酸铝、氧化铁、有机燃料、玉米蛋白饲料、阴湿泥浆、云母粉、药剂、颜料、重铬酸钾纸浆、酒糟渣等。

The equipment is widely used in food, chemical, pharmaceutical, building materials and other industries powder, granular material drying. Has been used in the series of dried products are: starch, glucose, fish meal, sugar, salt, lees, feed, gluten, plastic resin, coal, dyes and so on.

Ammonia ketone, ABC intermediates, ABS resin, ASC, white carbon black, benzene tea pyrazolone, tea meal, oxalic acid catalyst, accelerator m, dm, catalyst, precipitated charcoal, p-acetylglenzenesulfonamide, Amino acid salicylic acid, digitot, terephthalic acid, diethylanilinium, titanium dioxide, activated carbon, sodium fluorosilicate, fluorite, by-product ammonium sulfate, silica gel powder, synthetic resin, calcium sulfonate, poly Acrylic resin, chlortetracycline, sodium pyrosilicate, coffee dextrose, oral glucose, sodium sulfate, sulfide ore, phosphate rock, blue BB, PVC, molten phosphate, tetracycline, iron trioxide, calcium carbonate, Ore, copper, potato powder, tail coal, stearate, corn protein, pharmaceuticals, pharmaceuticals, iron oxide, rosacea and so on.

Vinyl acetate and polyethylene copolymer, cellulose acetate floc, catalyst, CMC, CT-1 resin, calcined gypsum, electrolytic manganese dioxide, ammonium anthraquinone sulfonate, fluorite, diatomaceous earth, silica gel catalyst, bone meal Potassium sulfate, aluminum sulfate, sodium sulfate, calcium phosphate, phosphoric acid esterified starch, dyestuffs, dyestuffs, Calcium citrate, slime, clay, clay, aluminum hydroxide, barium hydroxide, calcium lactate, food, cyanuric acid, gypsum pulp, lime, biological products, carbon black, calcium carbonate slurry, sludge slag, organic Chemicals Aluminum stearate, iron oxide, organic fuels, corn gluten feed, wet mud, mica powder, pharmaceuticals, pigments, potassium dichromate pulp, lees residue

4、技术参数Technical parameter

4.1.FG系列(FG Series)

型号Model |

水分蒸发量(Kg.h) |

功率 |

占地面积 |

效率efficiency(%) |

FG0.25 |

113 |

11 |

3.5*2.5 |

>70 |

FG0.5 |

225 |

18.5 |

7*5 |

>70 |

FG0.9 |

450 |

30 |

7*6.5 |

>70 |

FG1.5 |

675 |

50 |

8*7 |

>70 |

FG2.0 |

900 |

75 |

11*7 |

>70 |

FG2.5 |

1125 |

90 |

12*8 |

>70 |

FG3.0 |

1150 |

110 |

14*10 |

>70 |

FG3.5 |

1491 |

110 |

14*10 |

>70 |

4.2.QG系列(QG Series)

型号Model |

水分蒸发量(Kg/h) |

功率 |

占地面积 |

高度 |

QG 50 |

50 |

7 |

20 |

14 |

QG 100 |

100 |

13 |

32 |

14 |

QG 200* |

200 |

21 |

40 |

15 |

QG 250 |

250 |

24 |

64 |

15 |

QG 500 |

500 |

43 |

96 |

18 |

QG 1000* |

1000 |

100 |

120 |

18 |

QG 1500* |

1500 |

150 |

200 |

20 |

4.3.JG系列(JG Series)

型号 Model |

水分蒸发量(Kg/h) |

功率 |

占地面积 |

高度 |

JG 50 |

50 |

10 |

20 |

9 |

JG 100 |

100 |

20 |

32 |

11 |

JG 200* |

200 |

31 |

40 |

11 |

JG 250 |

250 |

32 |

64 |

13 |

JG 500 |

500 |

54 |

96 |

13 |

JG 1000* |

1000 |

135 |

120 |

15 |

JG 1500* |

1500 |

175 |

200 |

16 |