当前位置:主页>产品列表>混合搅拌设备>自动提升料斗混合机(方锥混合机)(CE)

自动提升料斗混合机(方锥混合机)(CE)

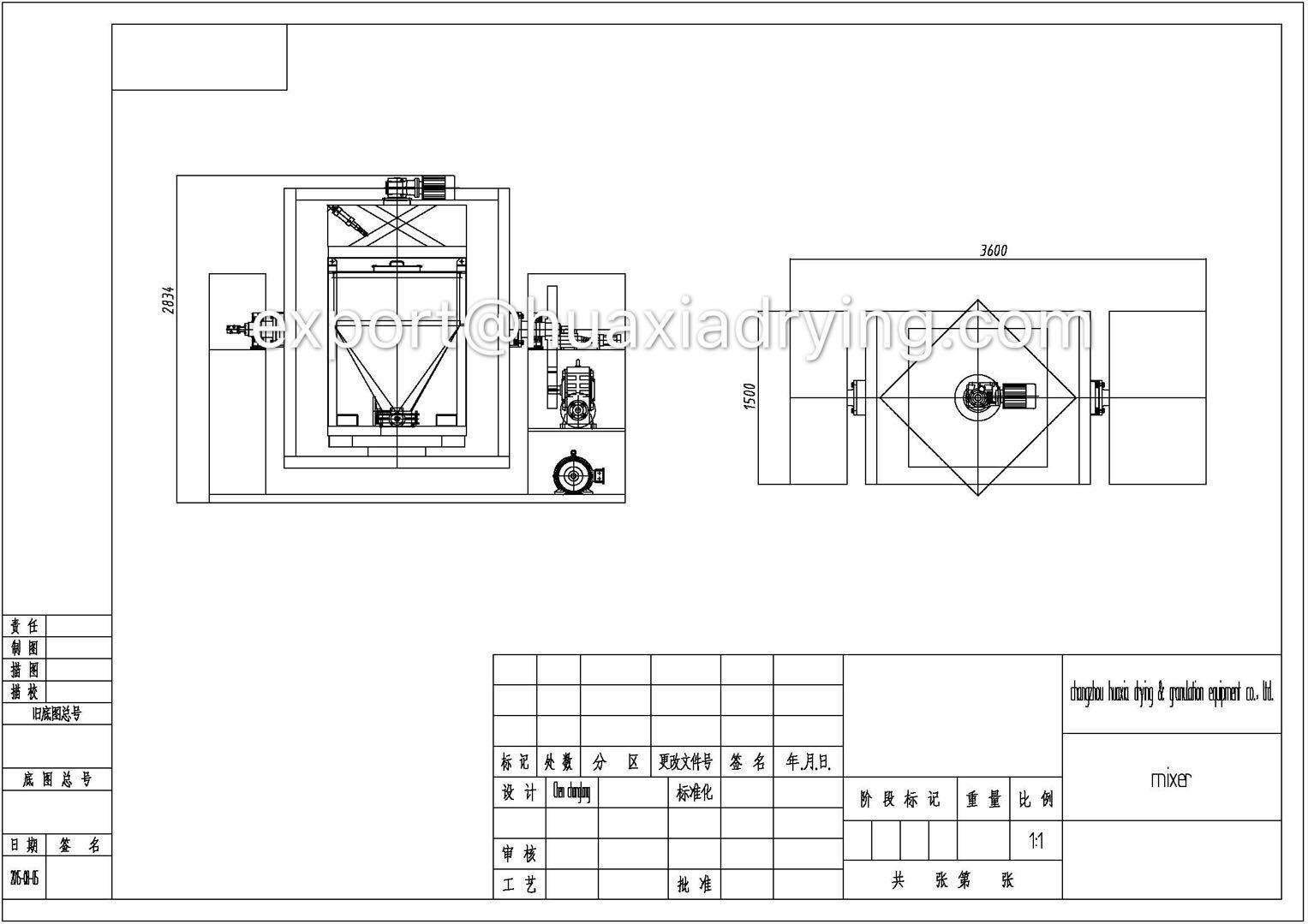

Automatic lifting hopper mixer ( Square Conical Mixer )

(CE Approved)

1. 概述( Description ):

自动提升料斗混合机能自动完成提升、夹持、混合、下降等全部动作。配一台自动提升料斗混合机及多个不同规格的混合料斗,就能满足大批量、多品种的混合要求,是药厂总混的理想设备。同时在制药、化工、食品等行业广泛使用。

Automatic lifting hopper mixer can automatically complete the lifting, clamping, mixing, move down actions . With an automatic lifting hopper mixer and a number of different mixing hopper, will be able to meet the large quantities, more varieties of mixed requirements,it is the ideal mixture of pharmaceutical industry ,It also widely used in the pharmaceutical, chemical, food and other industries .

2. 特点(Features):

本机的主要特点是:

1、使用PLC与变频调速使整机实现程序控制,采用方锥形料斗绕着对称轴旋转运动,物料在料斗中产生不对称、多方向、多维运动,回转体(混合料斗)与回转轴线成30°夹角,混合料斗中的物料随回转体翻动外,同时沿斗壁做切向运动,产生强烈的翻转和高速的切向运动,从而达到最佳的混合效果。。

Use PLC and frequency inverter to achieve the program control, with a smooth transmission, reliable structure, large amount of mixing, use square cone hopper rotary around the Symmetry axis ,the material in the hopper with asymmetric, multi- Movement, the rotor (mixing hopper) and the rotary axis at an angle of 30 °, the material in the mixing hopper turing with the rotating body, and material do tangential movement on the container wall, resulting in a strong flip and high-speed tangential movement, so as to achieve The best mixing effect.

2、设置红外线安全装置及防误操作装置的出料蝶阀,确保生产安全。物料可在同一容器中通过不同的工序段,不需要频繁地转料、加料等程序。有效地控制粉尘与交叉污染,减少物料的损失,控制物料的分层,优化了生产工艺,完全符合药品生产的GMP要求。

Set the infrared safety device and anti-misoperation device out of the butterfly valve to ensure production safety. Materials can be in the same container through a different block, do not need frequent transfer, feeding and other procedures. Effectively control dust and cross pollution, reduce material loss, control material stratification, optimize the production process, fully meet the GMP requirements of pharmaceutical production

3, with big storage capacity for the parameter, can store 20 different materials (or the same kind of material at different stages of production) process parameters, you can call different process directly .

3、参数储存量大,可储存20组不同物料(或同种物料不同生产阶段)的工艺参数,使用时直接调用即可。

4、采用了性能稳定、可靠的红外线光电传感器作为本机的安全防护装置之一,有效地保障了设备工作时的人员安全。

use stable performance, reliable infrared photoelectric sensor as one of the local safety protection device, effectively protect the staff safety when he operate the equipment .

4、技术参数Technical parameter

型号 |

SQM--600 |

SQM-800 |

SQM-1000 |

SQM-1200 |

SQM-1500 |

SQM-1800 |

SQM-2000 |

料斗容积 |

600 |

800 |

1000 |

1200 |

1500 |

1800 |

2000 |

系数装料 |

0.5~0.8 |

0.5~0.8 |

0.5~0.8 |

0.5~0.8 |

0.5~0.8 |

0.5~0.75 |

0.5~0.75 |

额定功率( KW ) |

4 |

5.5 |

5.5 |

5.5 |

5.5 |

7.5 |

7.5 |

最大回转高度( mm ) |

2400 |

2900 |

3000 |

3150 |

3300 |

3500 |

3700 |

静态外形尺寸(mm) |

3000 × 1970 × 2300 |

3000 × 1970 × 2460 |

3400 × 2150 × 2520 |

3400 × 2150 × 2680 |

3400 × 2150 × 2900 |

3550 × 2250 × 3100 |

3550 × 2250 × 3400 |

重量(t) |

1.8 |

2 |

2.4 |

2.8 |

3.2 |

3.6 |

4 |